AUTOMATION CONCEPT

Control technology – rational and individual

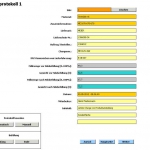

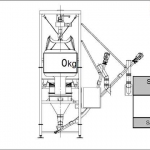

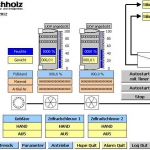

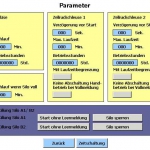

From controls in conventional technologies to fully automated silo installations with visualisations and connections to higher-level (control) systems we design individual operating units for every customer.

It is possible to integrate the controls of conveyors, the operation of customer-supplied machines, remote access via the operating network and further applications into the automation concept.

Our installations are designed and built in our own company, and they meet the highest quality requirements. Thus, customer requests can be implemented promptly and individually. Our longstanding experience in silo and plant engineering and construction enables us to combine the knowledge we have gained with your requirements in an ideal way. Your requirement is our challenge.